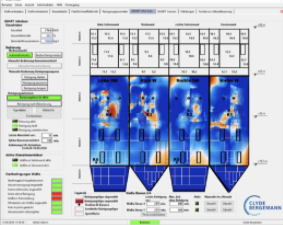

SMART Controls is a highly standardised control solution for optimised process flow and monitoring. The signal exchange to the DCS (Distributed Control System) takes place via all common industrial bus systems (Ethernet, Profibus, Modbus, etc.). Intuitive operation of the visualisation of the control system is possible via the integrated touch panel with display of all important properties and parameters.

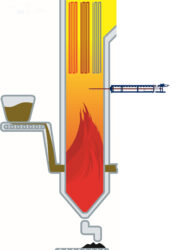

The intelligent boiler cleaning starts with the diagnostics of important process parameters. Different sensors continuously monitor those parameters and feedback key data for analysis of heat flux, flame and flue gas temperature, surface temperature and weight of deposits in the superheater and reheater area.

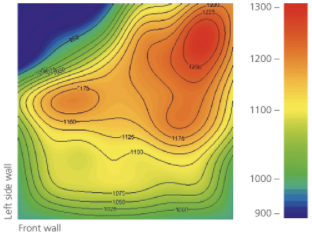

SMART IsoTemp is an optical pyrometer measurement system for flue gas temperature control monitoring in real-time. Based on the results, corrective actions in the firing operation can be carried out just in time, to keep the temperature in optimised operation and to stabilise the operation performance.

The 1D measurement system is for identification of the average FEGT (Furnace Exit Gas Temperature) for boiler start up process and monitoring, during the time the boiler is in operation. The 2D measurement system creates an Isothermal image to measure 2D flue gas

SMART InfraScan measures the surface temperature of the boiler wall in the furnace using infrared (IR) cameras. Deposits in the furnace act as an insulation layer leading to higher temperatures on the deposition layer itself. The measurements are carried out with an axial removable IR-camera carrier which is water cooled. Based on these measurements, SMART Furnace continuously monitors and evaluates the deposit situation in the furnace.

This enables SMART Furnace to calculate dynamically, cleaning figures and parameters depending on the deposit level.

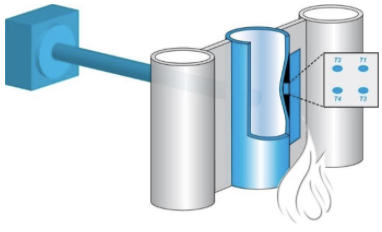

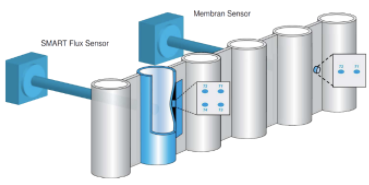

The SMART Flux Sensor is designed to directly measure the heat flux transmitted through radiation heat transfer surfaces of combustion boilers. The SMART Flux Sensor is used in combination with the SMART Cannon, F-149 or VS-H as a part of the SMART Furnace system to determine the actual cleanliness state of a specific area. SMART Flux sensors are configured, produced and calibrated for each installation individually.

By using several SMART Flux Sensors inside the furnace, the cleaning area is divided into cleaning zones. Each cleaning zone is represented by one SMART Flux Sensor.

The SMART Membrane Sensor is used in combination with the SMART Flux Sensors for continuous measurement of heat flux density. The measured temperature signals are bundled, filtered and amplified. It is used in combination with the SMART Furnace system to determine the current fouling condition of the furnace walls.

The patented SMART Multi-Point Sensor is measuring the temperature difference between back side tube crown and membrane and is providing the related heat flow information by using FEM (finite element method) to calculate the heat flux depending on the furnace wall arrangement.

The heat flux density is used to determine lowered heat flux by deposit accumulation on the membrane walls and thus an indication for cleaning in the respective cleaning area.

The information can be used to clean particular zones in the furnace with SMART Cannon, F-149 or VS-H as a part of the SMART Furnace System.

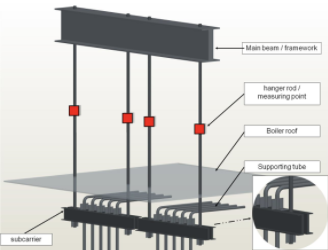

The SMART Gauge Sensor is designed to directly measure the weight of ash deposits within heat exchanger bundles, based on strain gauge technology.

The SMART Gauge Sensors are installed (bonded) on the hanging tubes outside the boiler and measure changes in weight caused by ash deposits building up on the heat exchanger surfaces.

The increasing deposits are indicated by an increase in weight. This localises areas of heavy deposits. The number and positioning of the sensors depends on the boiler geometry as well as the layout of the heating surfaces and the number and position of boiler-cleaning equipment.

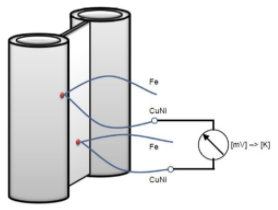

The Thermoprobe TS-O/TS-L is a measurement and analysis instrument to monitor the flue gas temperature in critical zones of the furnace exit area by using thermocouples up to 1,100°C. To avoid overheating of the probe tube head, Thermoprobe TS-L uses air as a cooling medium. For lower temperatures the Thermoprobe TS-O (without cooling media) is used.