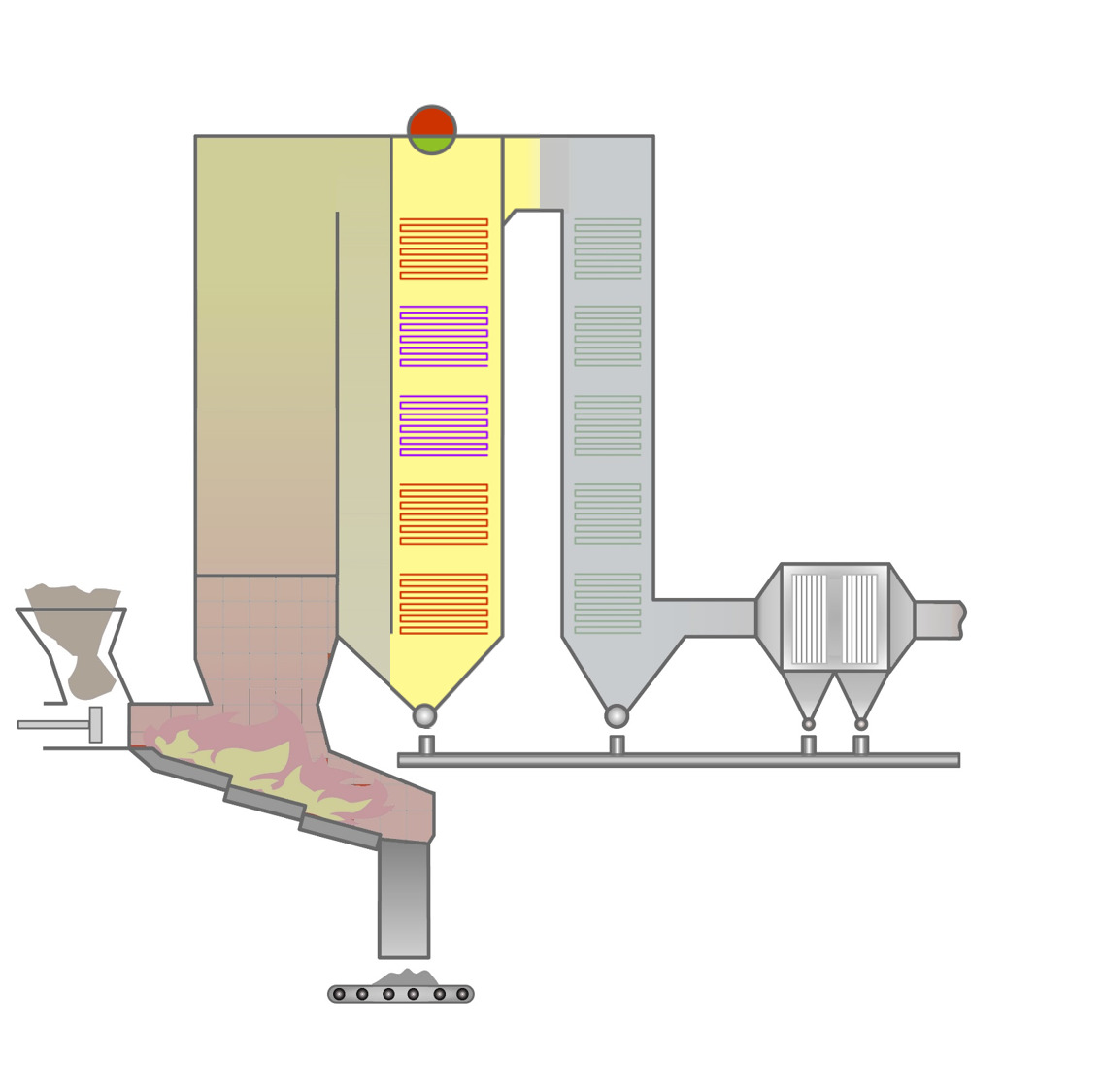

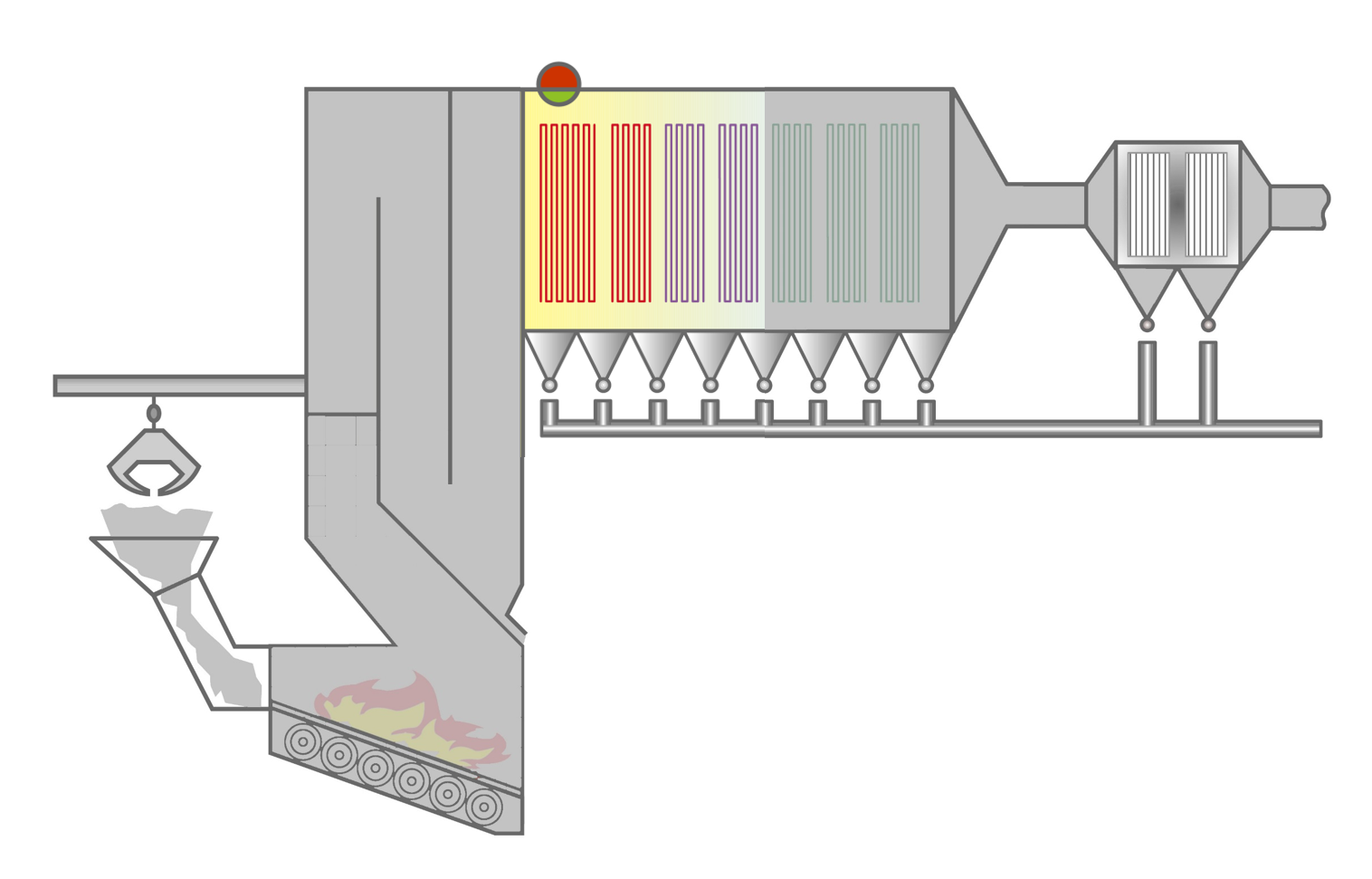

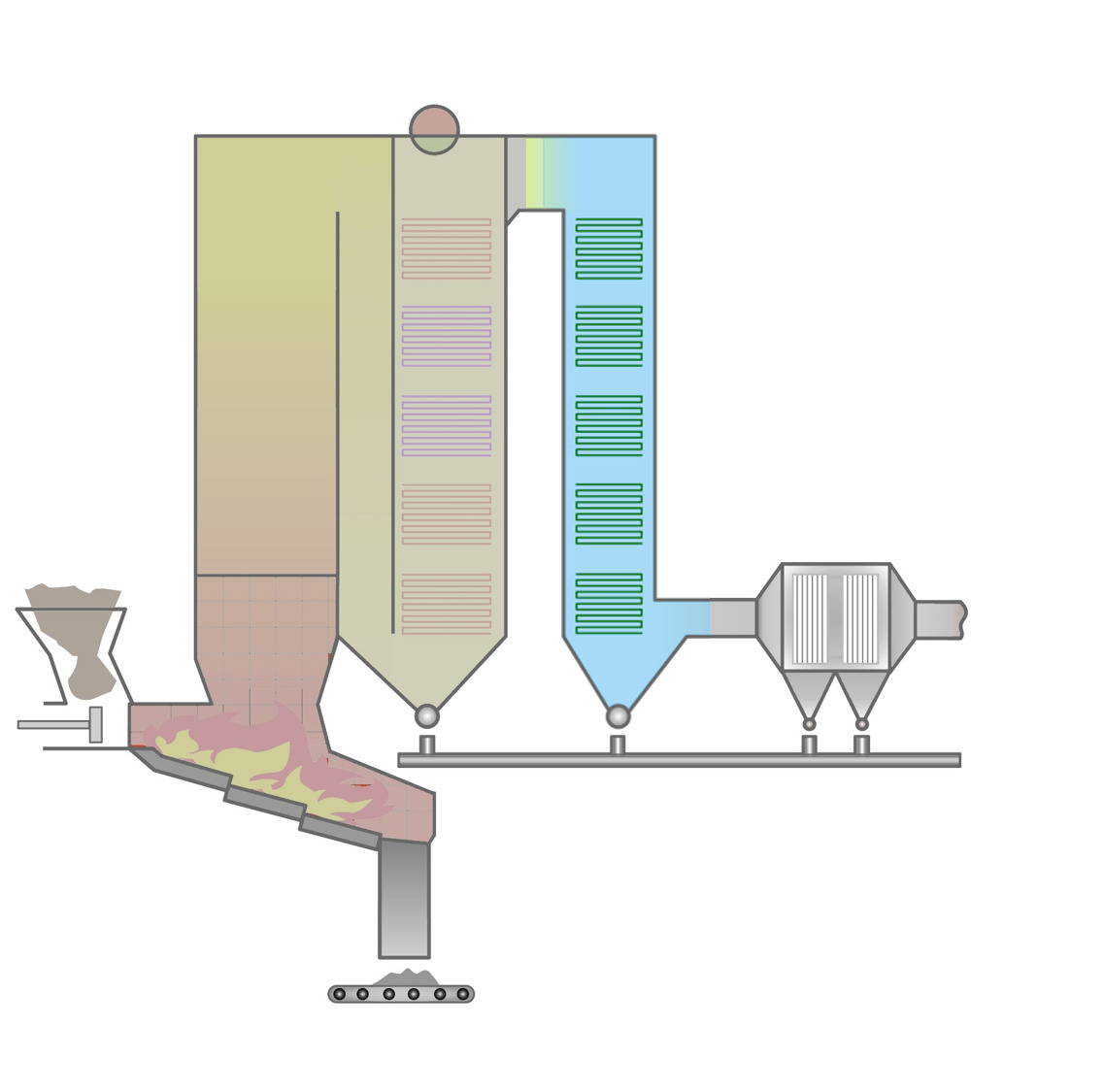

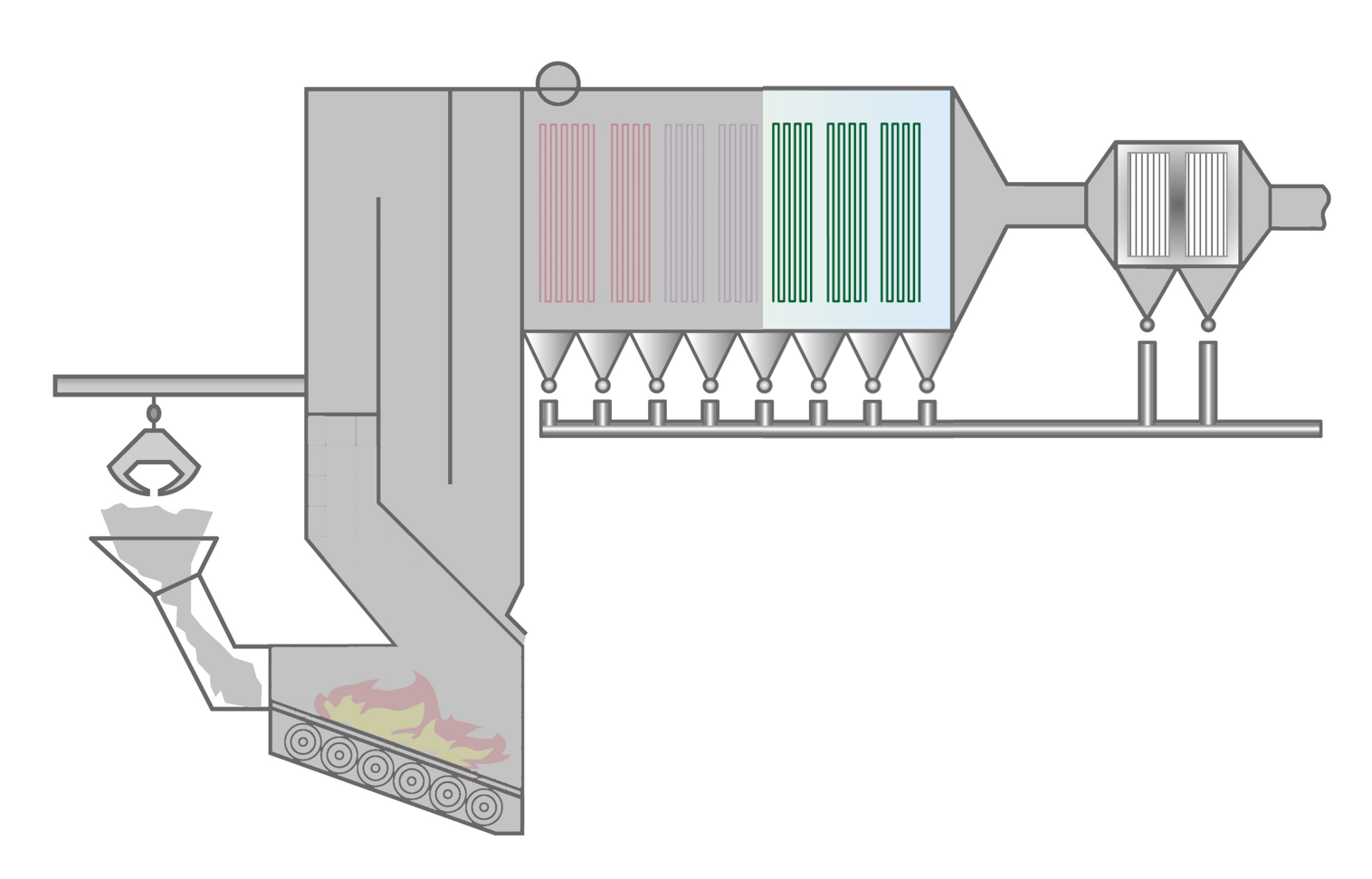

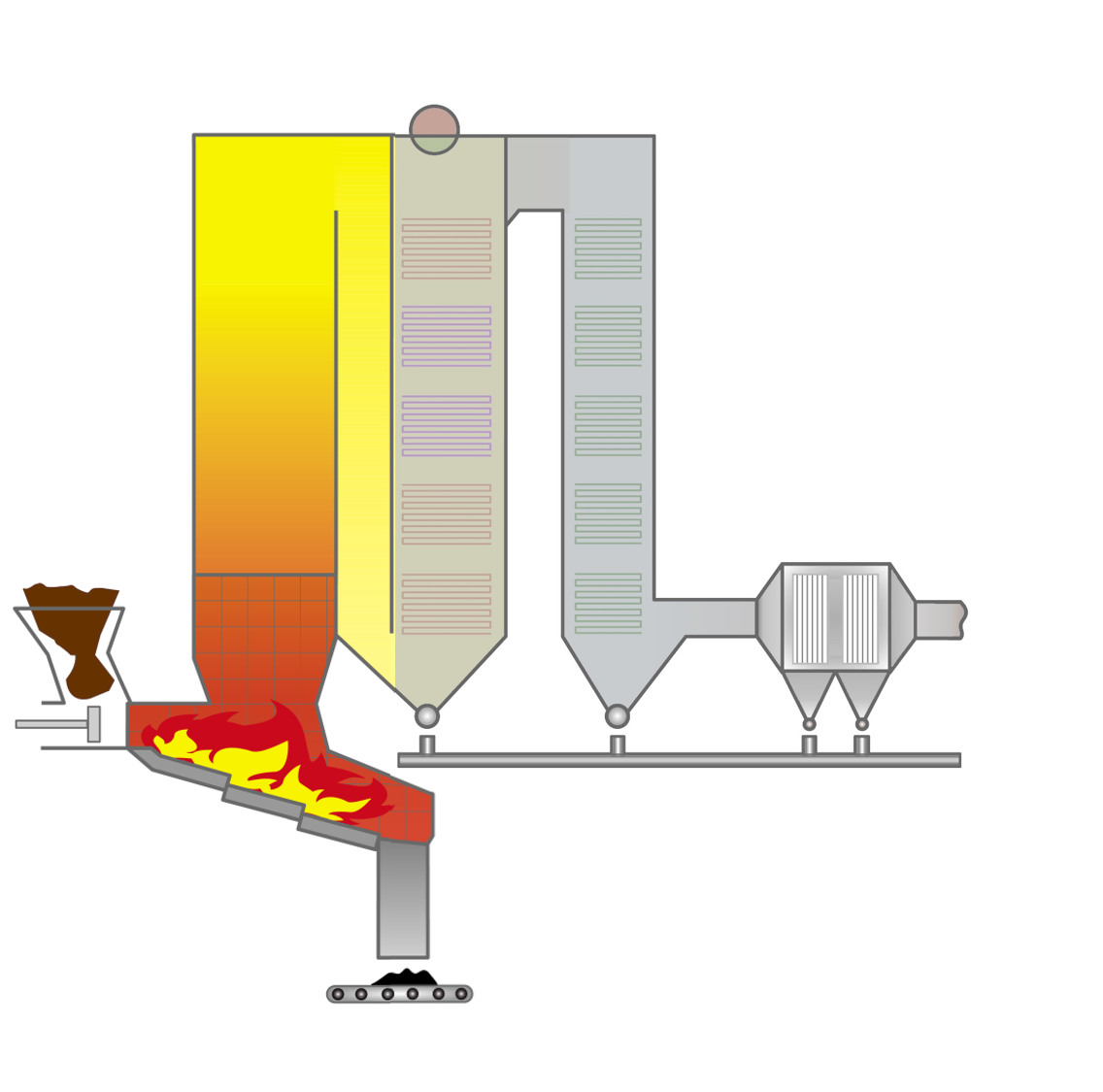

In the furnace and empty passes of Biomass plants, deposit build up on the heating and reaction surfaces causes reduced boiler efficiency, higher corrosion rates and unplanned shutdowns. The deposits tend to have an inhomogenous distribution due to a multitude of influencing factors.

Clyde Bergemann offers state-of-the-art products for cleaning the furnace and empty passes of all Biomass incinerators.

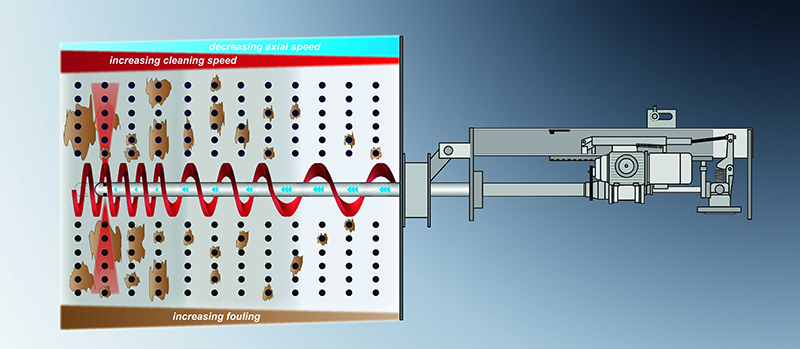

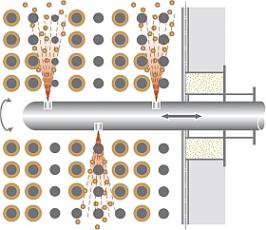

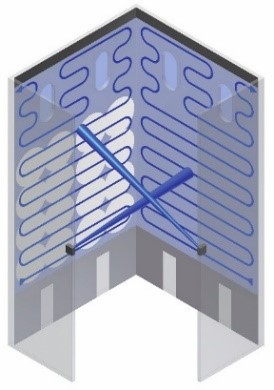

The SMART Cannon represents the most advanced furnace cleaning technology available, especially in larger-sized incinerators. Due to its specially developed control technology and precise positioning linear drive, the water jet creates a meander shaped pattern on the side and opposite wall, thereby ensuring timely and targeted cleaning.

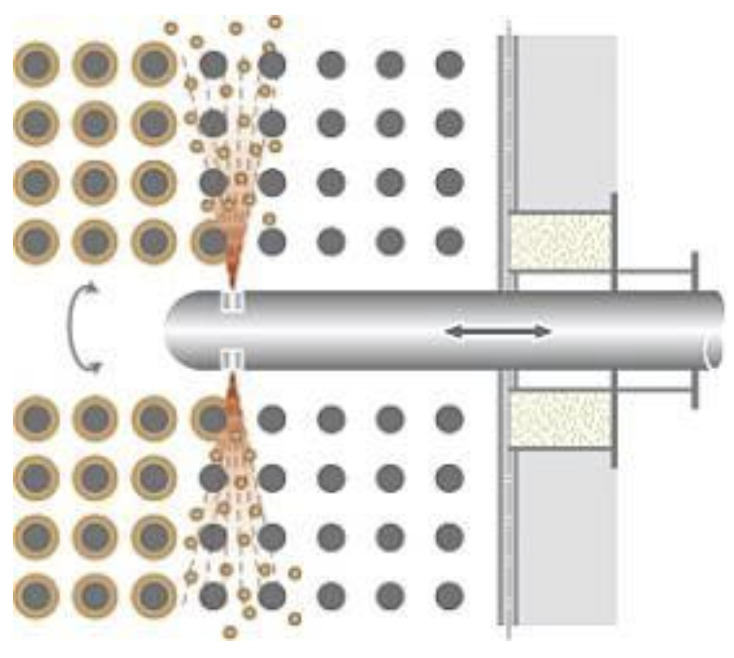

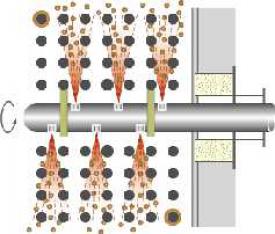

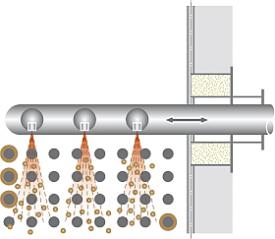

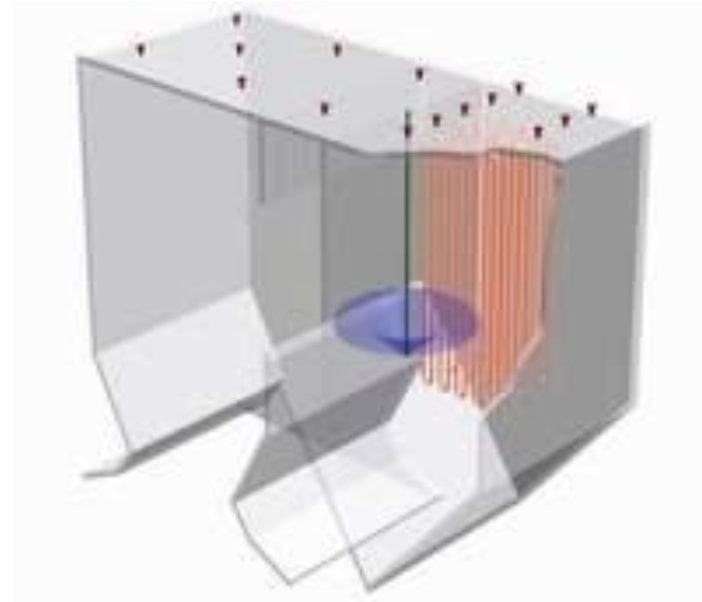

The SMART SCS uses water as the cleaning medium to remove fouling from furnaces and empty pass walls in any size of incinerators. Located on the boiler roof, the SMART SCS utilises an inverted umbrella nozzle or a multi-jet nozzle that sprays water in a continuous 360 degree pattern as it is being lowered into the furnace and empty passes.

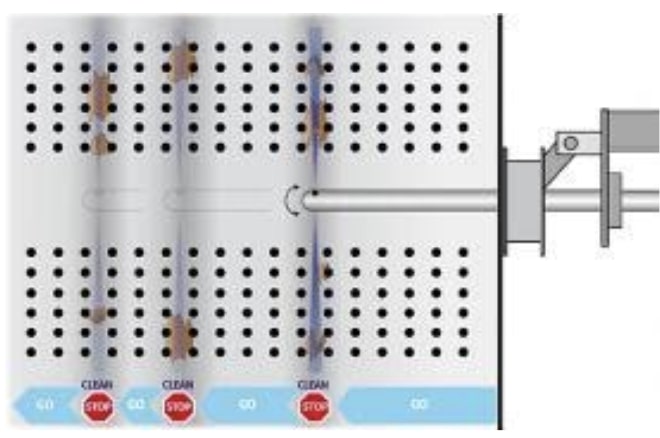

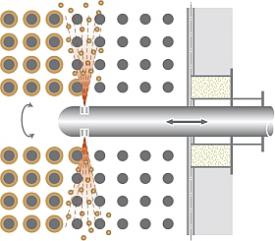

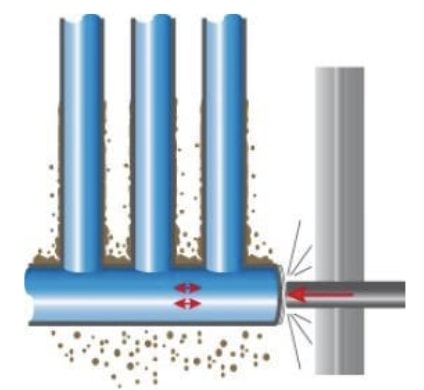

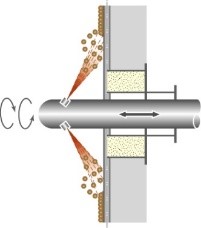

The conventional technology for cleaning the membrane wall heating surfaces is the VS-H Wall Blower, which removes slagging by using steam as the cleaning medium.

View Products

Wall Blowers: SMART Cannon, VS-H

SMART Shower-Clean System (SCS): SMART SCS