Clyde Bergemann has various Sootblowers in its portfolio, which can be used in Petrochemical site boilers with contaminated heating surfaces.

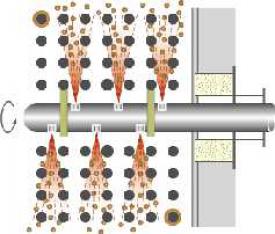

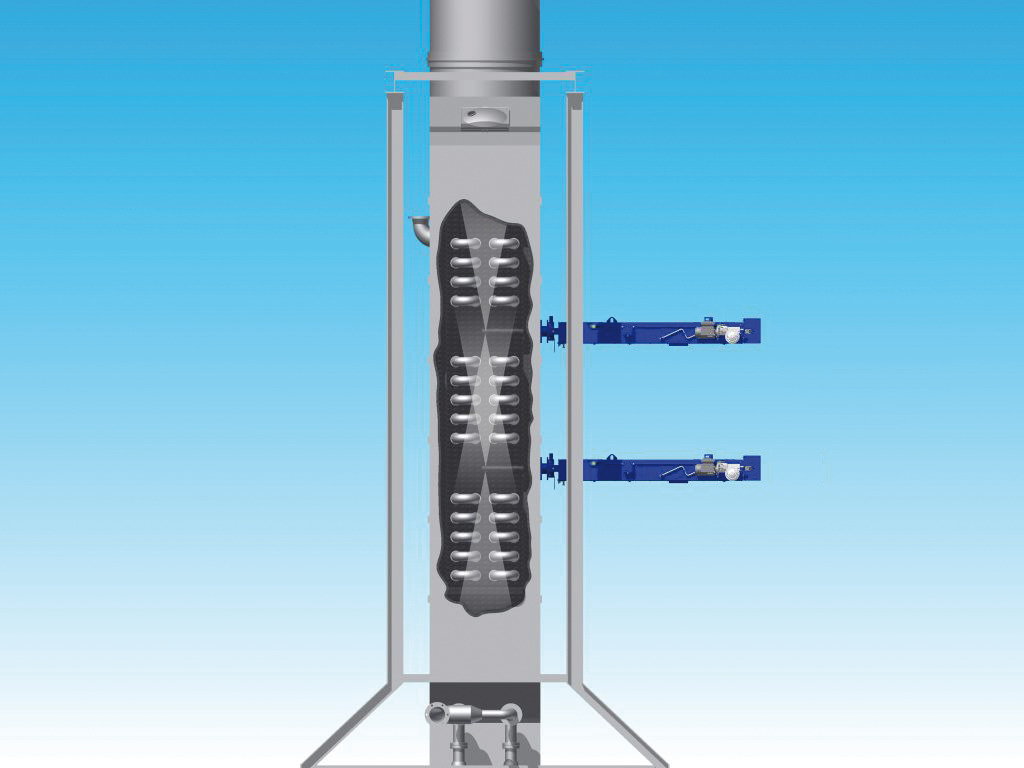

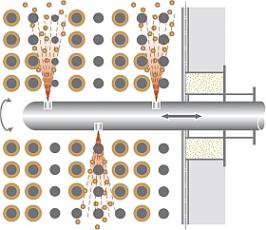

The Retractable Sootblowers are generally based on the principle that a lance tube with two opposite high-performance nozzles is helically moved into the flue gas path. For a travel distance of up to 10 metres, we recommend our PS-H Sootblower.

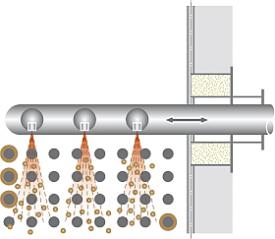

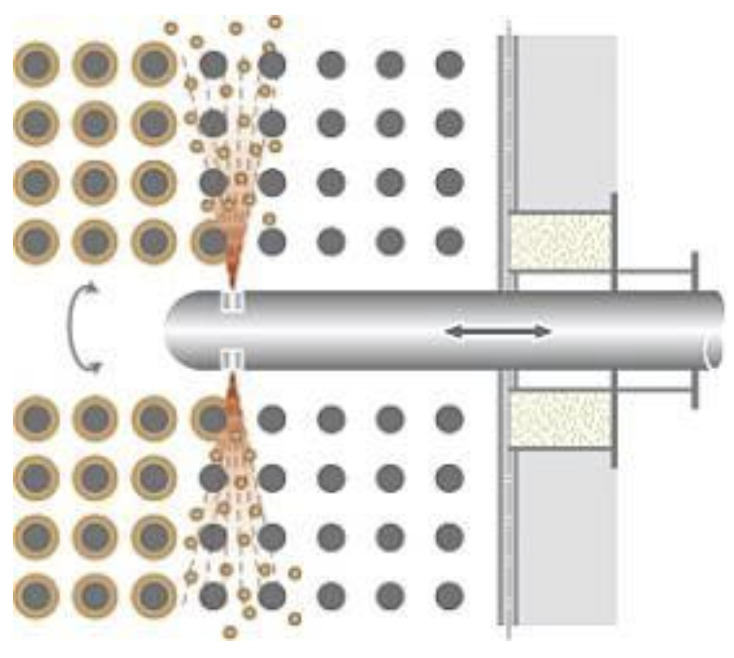

The Part-Retractable Sootblower will be used in superheater/ reheater areas. The blowing tube of the Part-Retractable Sootblower is equipped with high-performance nozzles over the whole length and is supported in the flue gas path. The PS-HB Sootblower is used for a travel up to 6 metres.

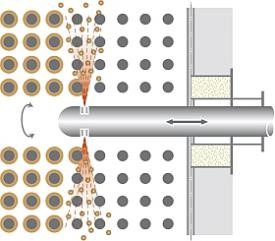

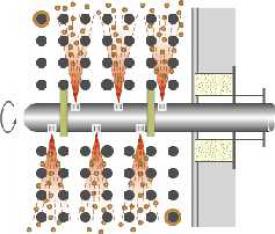

The Oscillating Sootblower is designed for the selected cleaning of specific boiler segments with heavy fouling and is available in retractable as well as part-retractable execution.

The Retractable Oscillating Sootblowers PS-P have blowing tubes with two high-performance nozzles, which are oscillating.

The Part-Retractable Oscillating Sootblowers PS-PB are equipped with high-performance nozzles over the whole length and are supported in the flue gas path.

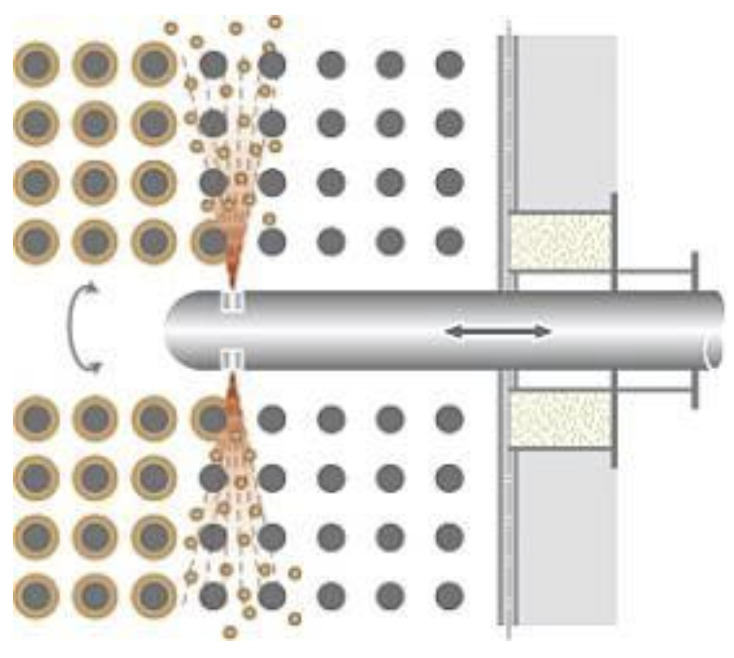

The DB Rotating Element Sootblower is designed to clean heating surfaces as well as heat exchangers with light fouling and flue gas temperatures < 500 °C. The blowing tube is equipped with nozzles over the whole length and rotates in the flue gas path without any axial movement.