Energy Recovery

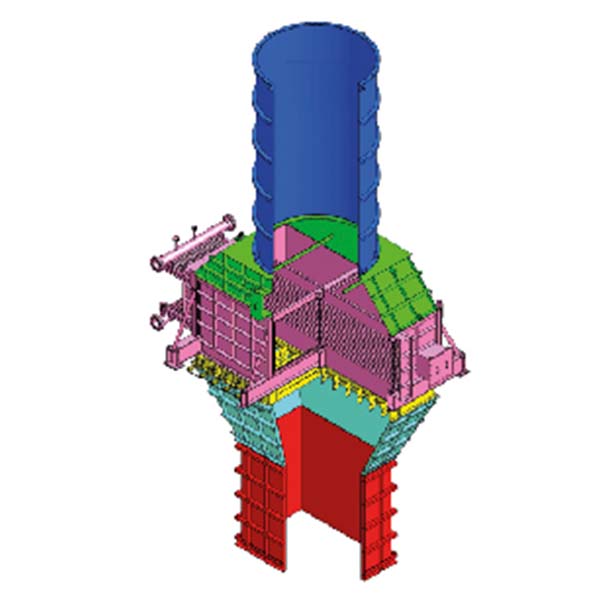

Energy Recovery comprises Economisers and other specialised products that maximise the reuse of process heat. For more than 60 years, we have been involved in the design and manufacturing of many types of waste heat recovery equipment.

Clyde Bergemann provides to the boiler and steam raising industry, locally designed and manufactured fuel Economisers and specialised heat exchange products for power generation and large industrial steam raising plants.

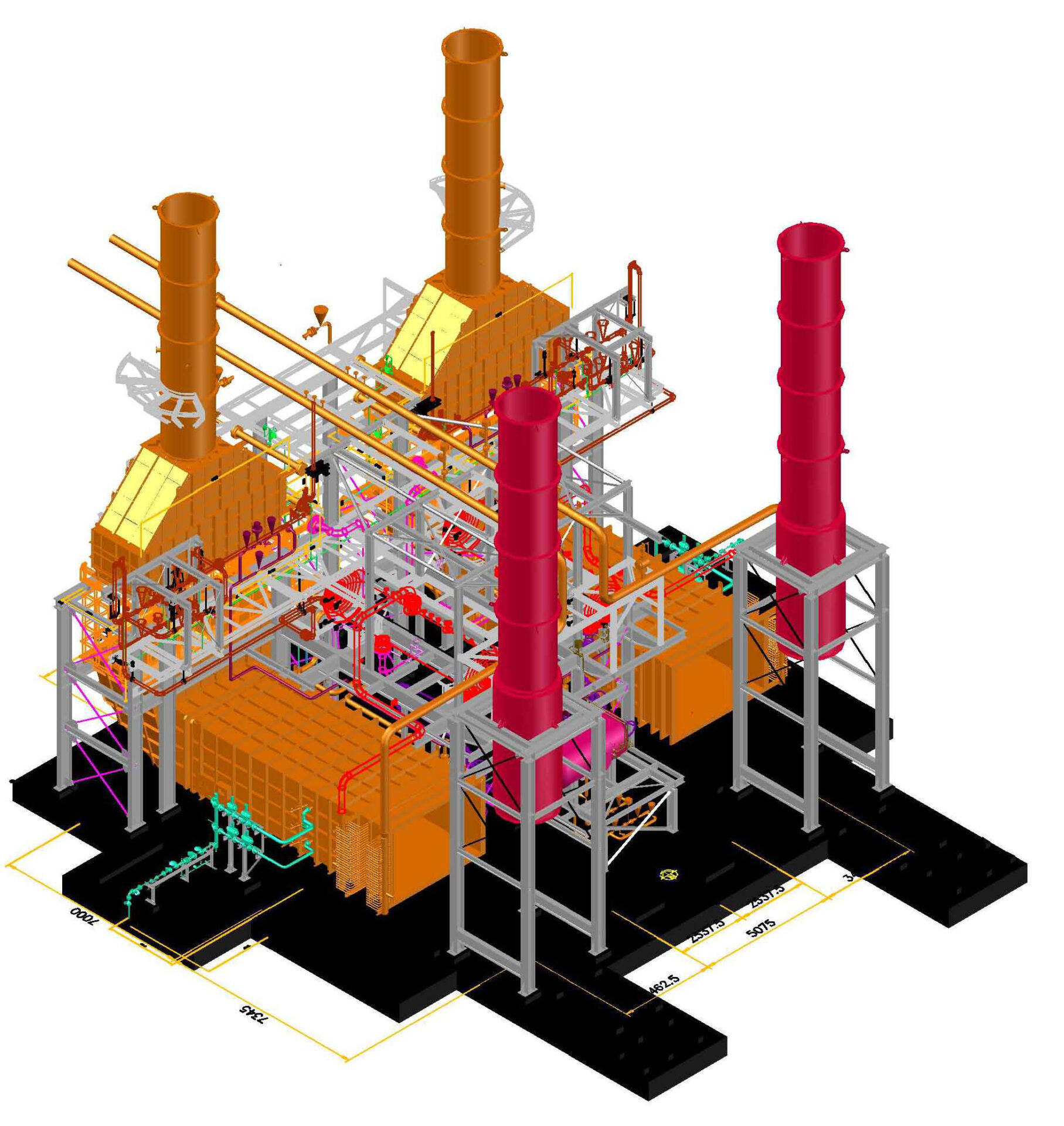

Our expertise lies in waste gas-to-liquid heat exchangers and waste gas-to-gas heat exchangers which absorb heat from the exhaust of reciprocating engines, gas turbines, furnaces, incinerators, boilers and other combustion equipment. The energy is transferred to process fluids such as water, steam, oil or air. Our equipment is built to AS, BS and ASME standards for both fired and non-fired vessels.

Our waste heat units are designed with integral bypass reducing the footprint required for heat recovery and consist of proven robust steel ‘H’® design heating surface. Typical markets include marine waste heat including FPSO/FLNG vessels and land-based waste heat. Our capacities range from 0.5 MW of heat recovered up to 50 MW of heat recovered. Additional capabilities include provision for supplementary firing and extra heating surface.

Our products show that technical improvements of conventional energy conversion processes can – in addition to alternative energy sources – make a valuable contribution to the sustainable transformation of the energy mix. Retrofitting existing plants with our energy recovery solutions has a significant positive environmental impact.

Products

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.

Benefits of using our products

- Recovery of valuable process heat for re-use

- Savings of primary energy

- Robust, low maintenance, long-lasting solutions

- CO2 savings

- Increased thermal efficiency to the process

- Ideal for retrofit applications

- Low maintenance costs

- Custom made designs are available

- Our products are also designed and manufactured to the following Pressure Vessel codes and rules:

AS1228

ASME Codes Section I and VIII Div. 1

ASME ‘S’ Stamp

Lloyds Register of Shipping

BS.1113 / BS.5500 / BS.2690