SMART Convection Matrix Clean

Operating Principle

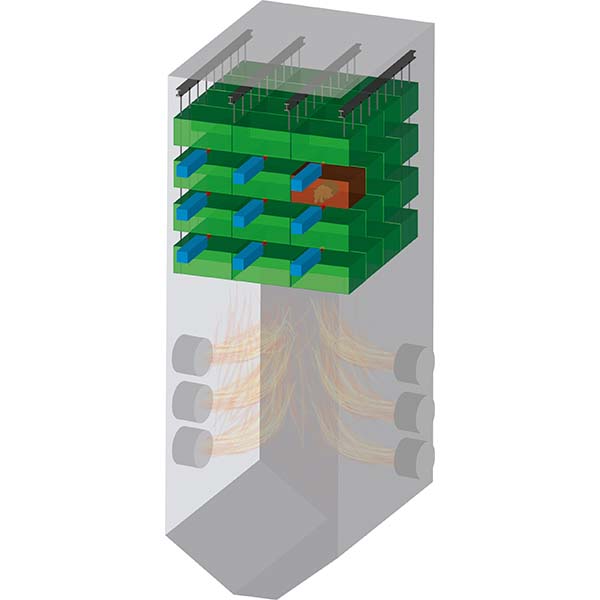

- The division of the boiler into zones is an important basis for the extensive flexibility of SMART Convection Matrix Clean

- Zone-based detection of the deposit status based on the intelligent combination of diagnostic information (SMART Gauge Sensor) and analytic data (TDM)

- Determination of a selective cleaning strategy for the convection part

- Selectable “closed loop” mode for assessing a conducted cleaning operation by evaluating direct sensor measurement values

Technical Summary

SMART Convection Matrix Clean is continuous monitoring and evaluation of the deposit situation in the convection part of a tower type steam generators and the determination of suitable and demand-oriented cleaning actions. The core tasks of SMART Convection Matrix Clean are:

- Continuously monitoring the fouling situation in the convection part

- Continuous validation of measurement data

- Analysis of fouling status

- Determination of a suitable and demand-oriented cleaning strategy

- For the determination of the fouling situation, the following are available: SMART Gauge Sensor, TDM

- General Application Area: Superheater, Reheater, Economiser

- Key Industries: Power Generation, Other Industrial Processes

Key Features

- Identification of fouling hotspots in the convection part of the boiler and selective cleaning of those hotspots only

- Fully automatic on-load control of the cleaning activities and thus ongoing automatic optimisation of the cleaning strategy

- Adaption of cleaning intensity according to the current measured cleanliness situation, depending on the used cleaning equipment

- Optimal usage of the cleaning media – cleaning activities will be reduced to the necessary amount by targeting cleaning

Product Benefits

- Demand-oriented, selective and automatic on-load furnace cleaning in the convective part

- Prevention of uncontrollable deposits

- Improved heat absorption in the convective part

- Reduced flue gas temperature after ECO

- More flexibility in the use of different fuel qualities and compositions

- Additional information on the steam generation process, e.g. flue gas temperature profile along the flue gas path

- Reduced consumption of cleaning media

- Lower influence on process due to targeted and reduced cleaning in the convective part

- Structured and easy-to-follow visualisation of the steam generator

YOU MAY ALSO BE INTERESTED IN…

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.