SMART Convection TDM

Operating Principle

- The division of the boiler into zones is an important basis for the extensive flexibility of SMART Convection

- Zone-based detection of the deposit status based analytic data

- Determination of a selective cleaning strategy for the convection part

- Selectable “closed loop” mode for assessing a conducted cleaning operation by evaluating analysis values

Technical Summary

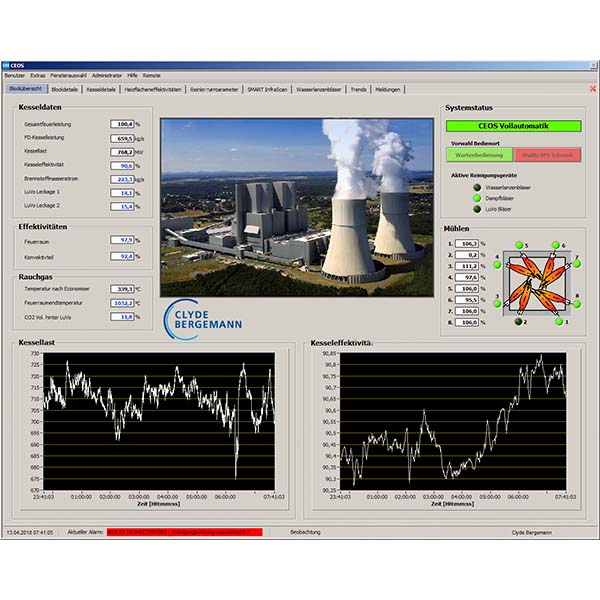

SMART Convection TDM is continuous monitoring and evaluation of the deposit situation in the convection part of steam generators and the determination of suitable and demand-oriented cleaning actions. The core tasks of SMART Convection TDM are:

- Continuously monitoring the fouling situation in the convection part

- Continuous validation of measurement data

- Analysis of fouling status

- Determination of a suitable and demand-oriented cleaning strategy

- General Application Area: Superheater, Reheater, Economiser

- Key Industries: Power Generation, Other Industrial Processes

Key Features

- Identification of fouling hotspots in the convection part of the boiler and selective cleaning of those hotspots only

- Fully automatic on-load control of the cleaning activities and thus ongoing automatic optimisation of the cleaning strategy

- Adaption of cleaning intensity according to the current measured cleanliness situation depending on the used cleaning equipment

- Optimal usage of the cleaning media – cleaning activities will be reduced to the necessary amount by targeting cleaning

Product Benefits

- Demand-oriented, selective and automatic on-load furnace cleaning in the convective part

- Prevention of uncontrollable deposits

- Improved heat absorption in the convective part

- Reduced flue gas temperature after ECO

- More flexibility in the use of different fuel qualities and compositions

- Additional information on the steam generation process, e.g. flue gas temperature profile along the flue gas path

- Reduced consumption of cleaning media

- Lower influence on process due to targeted and reduced cleaning in the convective part

- Structured and easy-to-follow visualisation of the steam generator

YOU MAY ALSO BE INTERESTED IN…

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.