The design of most diesel powered ships will include a Waste Heat Recovery Unit (WHRU), the purpose of which is to efficiently recover energy from the exhaust gases downstream from the gas turbine. It can produce superheated steam, saturated steam, hot water and hot oil for power generation, heating and process duties.

Although their primary function is to maintain the operational efficiency of these WHRU’s by preventing the build-up of deposits on the heat exchange surfaces which occurs during normal operation, Clyde Bergemann Sootblowers also play a key role in reducing the level of harmful emissions and minimise the risk of a soot fire occurring whilst the ship is in service.

Clyde Bergemann has various Sootblowers in its portfolio, which can be used for cleaning the plain or finned tubes in these Waste Heat Recovery Units (WHRU).

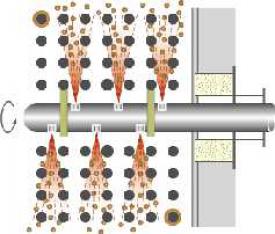

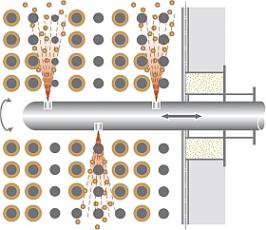

The DB Rotating Element Sootblower is also designed to clean WHRU surfaces with light fouling and flue gas temperatures < 500 °C. The blowing tube is equipped with nozzles over the whole length and rotates in the flue gas path without any axial movement.