Operating Principle

- Due to its specially developed control technology, the water jet creates a meander shaped pattern on the side and opposite wall

- The water penetrates into the pores, evaporates and causes an abrupt increase in the volume, resulting in deposit removal

- The blowing tube movements are directly and continuously monitored.

- Use of different combinations of nozzle sizes and blowing pressures to clean opposite walls at a distance of up to 25m

Technical Summary

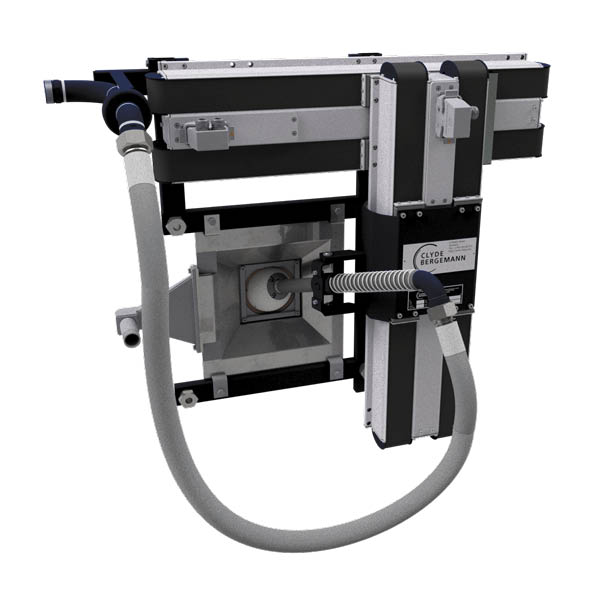

The SMART Cannon represents the most advanced furnace cleaning technology available. With over 2800 installations worldwide, the SMART Cannon has proven to be the most effective and reliable furnace cleaning device in the market. The SMART Cannon uses water as the cleaning medium and is designed as a three-dimensional cleaning device with “X” and “Y” axis control facilitated through self-contained, modular linear drives designed to travel approximately 45 degrees in each direction and the “Z” axis controlled through varying water pressure during its operation.

- Cleaning Medium: Water

- General Application Area: Furnace

- Cleaning Arc: 90 ° horizontal / 90 ° vertical

- Key Industries: Power Generation, Waste-to-Energy, Biomass, Other Industrial Processes

Key Features

- Heavy-duty cleaning system suited for high furnace temperatures

- Horizontal and vertical linear drive modules with specially extruded aluminium frames

- Linear module drive with state-of-the-art position transmitting sensors for precise jet positioning

- Compact design

- Stainless steel blowing element with high performance nozzle

- Heat resistant, air-cooled ball joint at furnace wall interface

- Hollow crimp box construction to facilitate airflow from fan to ball joint

- Complete set of necessary instrumentation with pump skid

Product Benefits

- Increased plant availability due to reliable boiler cleaning, resulting in efficient plant operation

- Single cannon can clean a large area of the furnace

- Cleans areas difficult to access, e.g., hopper, centre wall

- Cleaning coverage in the boiler improves up to 90% in comparison to conventional wall blowers

- Reduced Furnace Exit Gas Temperature (FEGT) and increased boiler efficiency through improved heat transfer

- Reduced corrosion rate

- Shorter boiler outage period

- Cleaning figures can be individually adjusted to boiler geometry

- Prevention of uncontrolled water application into the furnace

- Reliable and simple to maintain

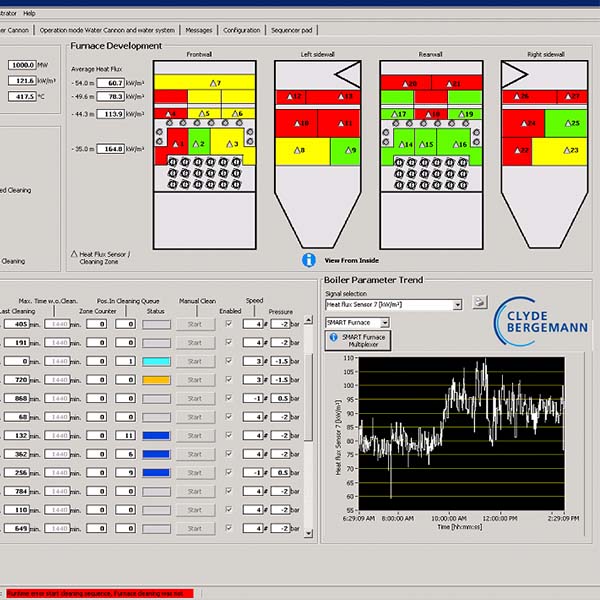

- Intelligent, flexible operation, in conjunction with SMART Furnace

YOU MAY ALSO BE INTERESTED IN…

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.