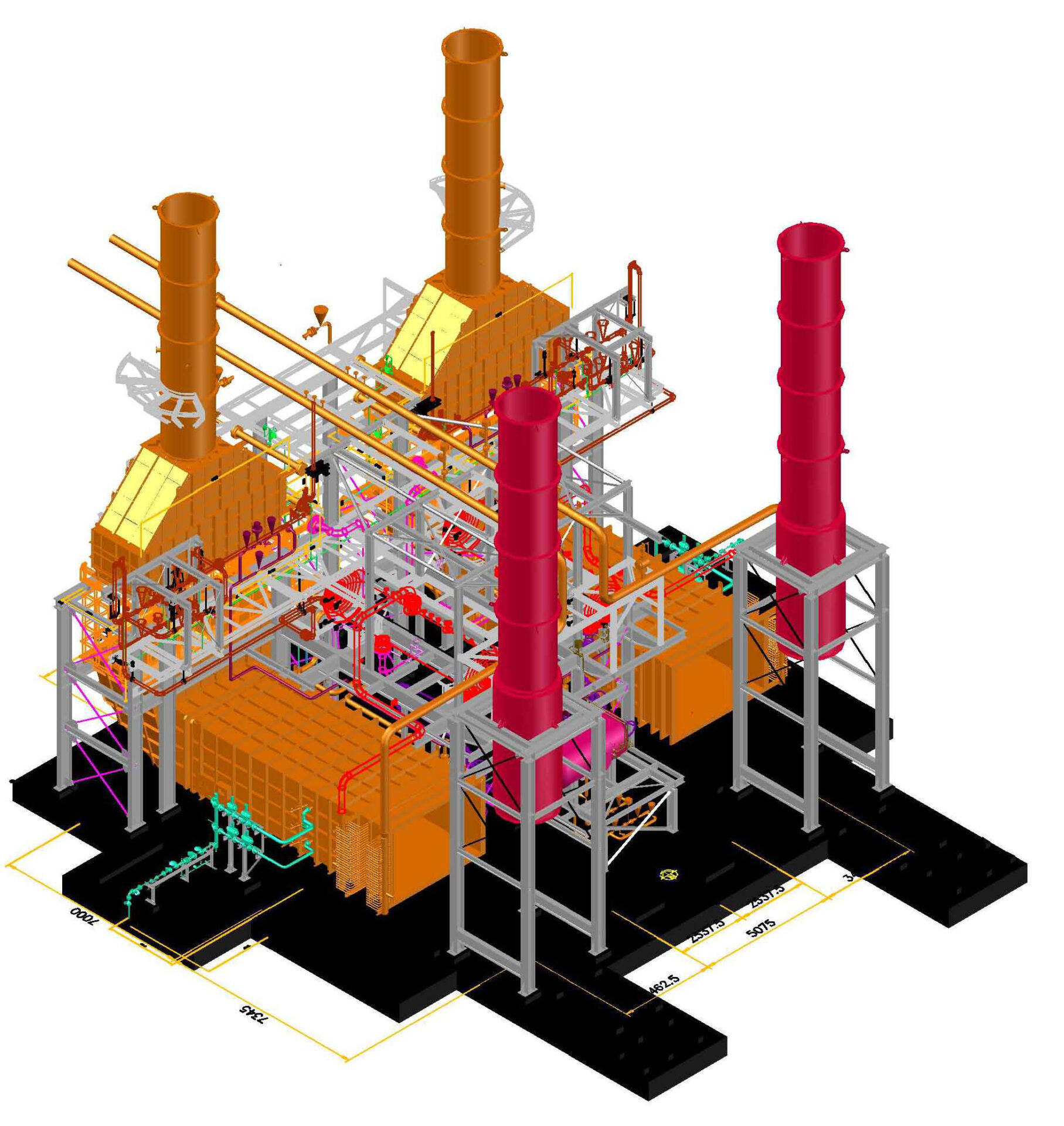

Heat Recovery Steam Generator (HRSG)

Operating Principle

- Robust design proven in the field for more than 60 years

- Scope of supply incorporating dampers, diverters, expansion joints and bypass stacks

- Process steam or power generation

- Steel H® / Double H® or spiral fin design options

- Up to 100 t/h steam generation

- Forced circulation speciality

Technical Summary

HRSG’s can be used for either additional power generation in a combined cycle form or providing steam direct to process. Our HRSG’s enable efficient heat recovery from Gas Turbines, compressors or Engines and Diesel Engine exhaust gas streams. Ideal for brownfield or greenfield development projects, Clyde Bergemann can engineer a highly efficient, robust, long-lasting energy recovery surface to suit your needs.

-

Key Industries: Biomass, Marine, Oil and Gas, Power Generation, Waste-to-Energy

Key Features

- Onshore & offshore designs

- Material flexibility to suit applications

- Supplementary firing available

- Auxiliary options available – support steelwork, ladders and platforms, pumps, insulation

- Simple installation – modular options or large transportable pieces

Product Benefits

- Immediate decarbonisation benefits realised

- Potential to reduce Carbon Tax for end users

- Low maintenance costs

- Smaller footprint for restricted applications

- Proven Louvre Damper design in-house reducing complicated interfaces

- Robust and long-lasting low maintenance energy recovery surface

- Low fouling easy to clean energy recovery surface

YOU MAY ALSO BE INTERESTED IN…

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.