SMART Rapping System

Operating Principle

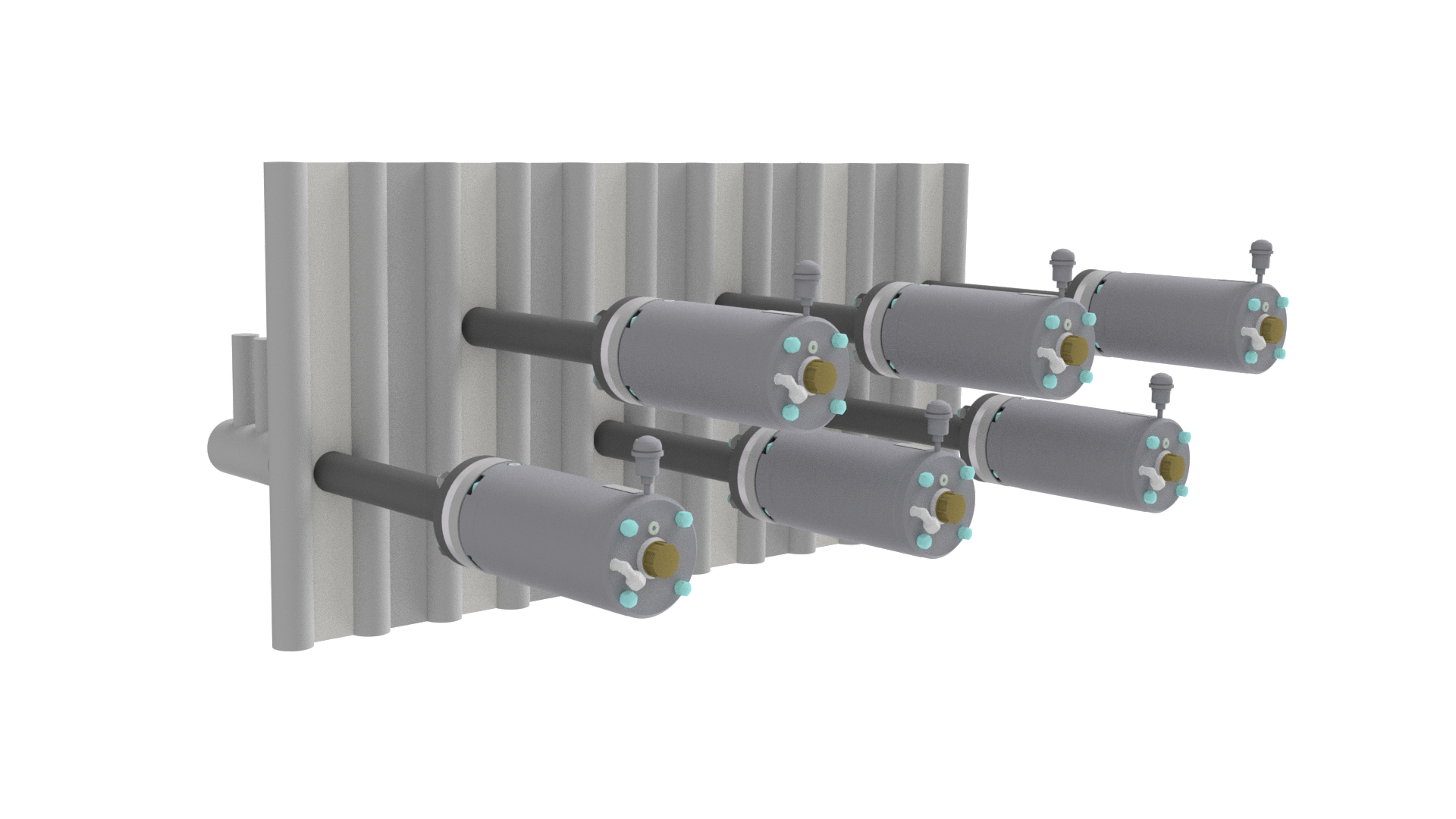

- Rapping the fouled heat exchanger tube bundles with pneumatic cylinders induces oscillations, which shakes off the build-up deposit

- Individually adjustable impact energy allows targeted optimisation of the heating surface cleaning procedure, ensuring that the overall efficiency of the evaporators, superheaters and economisers are kept consistently high

Technical Summary

A rapping device system is a special product for cleaning horizontal passes, especially for waste-to-energy plants and other industrial applications. Rapping device systems can be applied to remove deposits from the heating surfaces without any additional cleaning medium like steam, air or water.

- General Application Areas: Superheater, Reheater, Economiser

- Key Industries: Waste-to-Energy, Other Industrial Processes

Key Features

- Pneumatically operated independent impact cylinders

- Impact Energy: Cylinders with 120 J, 150 J and 200 J output

- Highly flexible & optimised cleaning by individually adjusting impact energy and frequency of ramming based on the fouling degree

- Integrated force compensation

- Low noise level

- Low air consumption for activation of single rappers

- Sealing air to prevent the admission of flue-gases in case of positive pressure mode

- Optical operating pressure indicator (optional)

- Wear indicator on cylinders to provide constant check to operating staff

- Profibus connection to process control system (optional)

Product Benefits

- Increased plant availability due to reliable cleaning, resulting in efficient plant operation

- Prevents fouling in convection areas of the boiler

- Increased boiler efficiency through improved heat transfer

- Reduced gas exit temperatures

- Compact design through direct mounting on rapping points, thus eliminating need for steel structure (as compared to conventional rapping systems)

- No air or steam needed as blowing medium

- Low maintenance expenses, less spare parts and reduced operating costs

- Comfortable operation and feedback to the control room

- Intelligent, flexible operation, in conjunction with SMART Clean Compact

YOU MAY ALSO BE INTERESTED IN…

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.