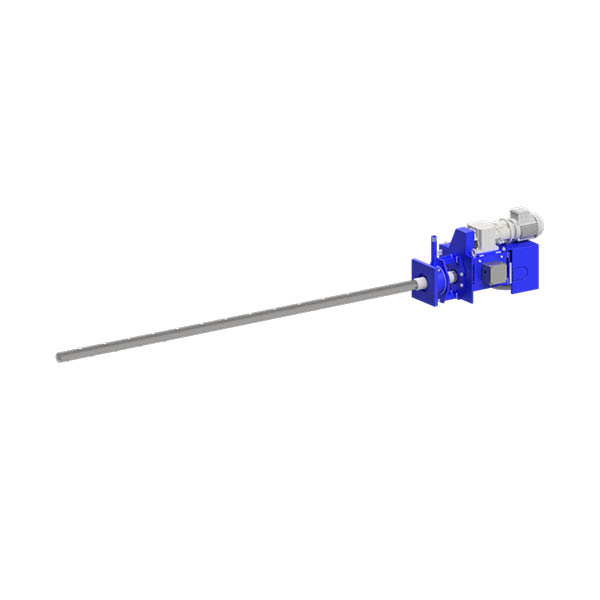

Rotating Element Sootblower DB

Operating Principle

- The blowing tube is equipped with high-performance nozzles over the whole length and rotates in the flue-gas path

- During the blowing process, the blowing tube performs a prescribed number of rotations

- A cam-controlled valve opening enables cleaning of specific segments

- The blowing process ends when the prescribed number of rotations have been performed

- Blowing tube remains in flue-gas path

Technical Summary

The DB Rotating Element Sootblower is designed to clean convection surfaces, as well as heat exchangers with light fouling and flue-gas temperatures < 500 °C. The blowing element always remains in the boiler, supported by element bearings usually attached to the boiler tubes. Specially designed nozzles are located on the element for each specific installation. Also suited for hazardous area conditions.

- Cleaning Medium: Steam, Air

- General Application Areas: Reheater, Economiser, Fired Heater Convection Section

- Travel Range: Fixed (only rotational movement)

- Cleaning Arc: 360 ° (typically with 3 cycles per day)

- Key Industries: Waste-to-Energy, Biomass, Marine, Oil & Gas, Other Industrial Processes

Key Features

- Poppet valve with adjustable throttle disc for easy setting of the blowing pressure

- Temperature-resistant blowing element with high performance nozzles

- Compact steel framework

- Integrated gear motor for rotating movement

- Rotation monitoring by limit switch

- Wall box with sealing elements corresponding to boiler pressure mode

- Sealing and scavenging air piping with dedicated fan (optional)

- Cantilever support design eliminates need for rear support requirements

Product Benefits

- Increased plant availability due to reliable boiler cleaning, resulting in efficient plant operation

- Increased boiler efficiency through improved heat transfer

- Compact design with minimal footprint to fit into available space

- Reliable and simple to maintain

YOU MAY ALSO BE INTERESTED IN…

Spare parts & service

Our services, knowledge and experience are utilised to provide optimal support and are tailored specifically to individual customer requirements. From spare parts to surveys, maintenance and training – we cover your needs.